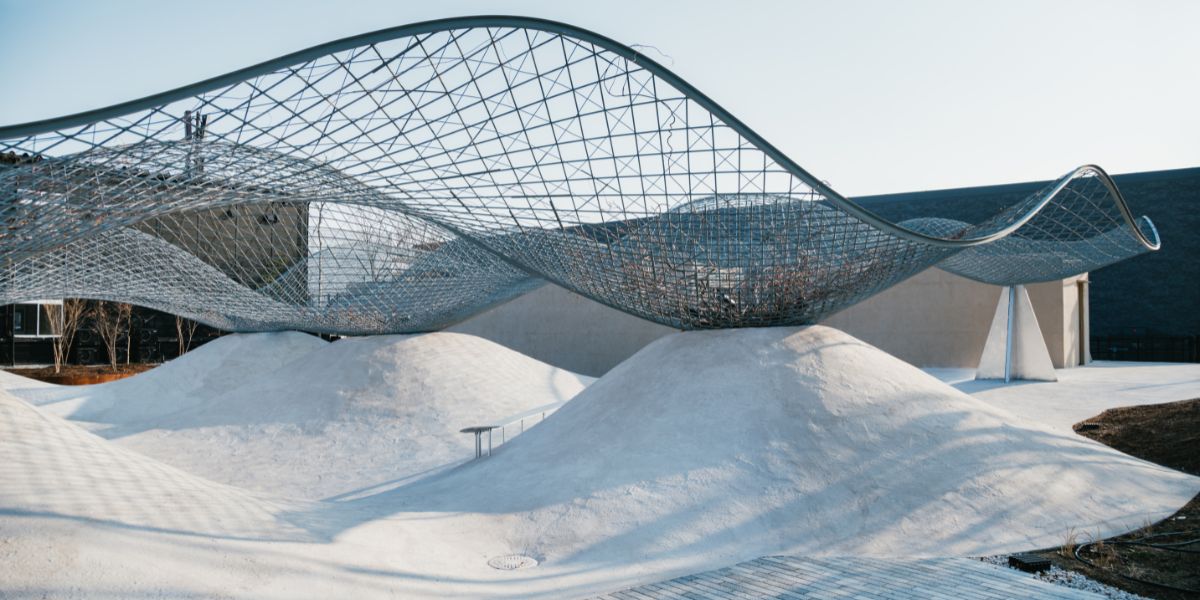

Discover the 900 m² outdoor space created with MORTEX® coating

In rest area number 4 – a 900 m² public space where visitors seeking peace and quiet can catch their breath in a gently shaded, undulating landscape – our MORTEX® mineral flooring makes a subtle yet striking impression.

The use of our coating in this project is no coincidence. Japanese construction company Kadowaki Construction was looking for a material that was both functional and aesthetic: crack-resistant, colour-fast and able to blend in perfectly with the natural environment. Of all the options considered, only our MORTEX® mineral coating met all the criteria. Its warm, earthy colour allows the surface to blend into the surrounding ground. This aesthetic is perfectly in tune with the Japanese sensibility for simplicity and harmony with nature.

“We didn’t consider the MORTEX® brand at first. We were thinking of a classic coloured mortar, gravel paving or even resin-based treatments. But we kept coming up against technical limitations, such as cracking, the risk of slipping or colour variation due to humidity. Colour retention was a real challenge given the changing Japanese climate. Thanks to its neutral, pigmentable base, MORTEX® mineral coating offered great creative freedom. By playing with precisely measured pigments, we were able to achieve a stable, earthy colour that was perfectly suited to the environment. The idea of using MORTEX® plaster came up during an informal discussion with an acquaintance. He told me about how the MORTEX® system works, and as we discussed its technical properties, I realised that it was the product we needed. And it turned out to be a masterstroke. ”

– Shinichi Kadowaki, Project Manager

The collaboration went very smoothly, thanks to a team of Japanese craftsmen experienced in applying our coating, including Ishihara Plastering and Ribre, both official trainers for the MORTEX® brand in Japan. Three to four samples were developed before the final design was approved, with particular attention paid to adhesion in wet weather.

No fewer than 3,570 people worked together to create this rest area, a project that took 299 days to complete. Even the washbasins in the sanitary areas were finished with MORTEX®. The most intense period was between November and December 2024, when contractors were working simultaneously inside and outside, making coordination particularly challenging. To keep an overview, a temporary office was even set up in the building.

Since 1999, we have been developing our presence in Japan, a demanding and inspiring market in which we are particularly committed. We now have 17 sales outlets and 8 official trainers with whom we organise four training courses every month on the use of our registered trademarks MORTEX® and BEALSTONE®, which equates to nearly 500 craftsmen trained each year in Japan. In addition, we host advanced training sessions here in Belgium, with four courses per year for groups of ten Japanese craftsmen who come to further their expertise.

“The fact that our product has been chosen for such a visible and intensively used part of the World Expo is very special. I see it as the culmination of years of work by our R&D team to achieve the best possible product, as well as the result of ever-stronger collaboration with our international partners. It proves once again that sustainability, aesthetics and innovation can go hand in hand in an admirable way. ”

– Barbara Thiry, CEO of BEAL International

Beyond our product, we are delighted to see our region, our local industry and, more broadly, our country showcased on the world stage. This project, with its bold and resolutely contemporary design, is a real architectural statement. It is a great recognition of our Belgian know-how and a magnificent international showcase for our product, which is designed and manufactured in Fernelmont, in the Namur region.

Those who wish to discover the rest area in person can visit the Osaka World Expo until 13 October 2025 inclusive.

Project credits:

- Architects: MIDW+ Niimori Jamison

- General contractor: KADOWAKI CONSTRUCTION Co., Ltd.

- Photographer: Yosuke Ohtake